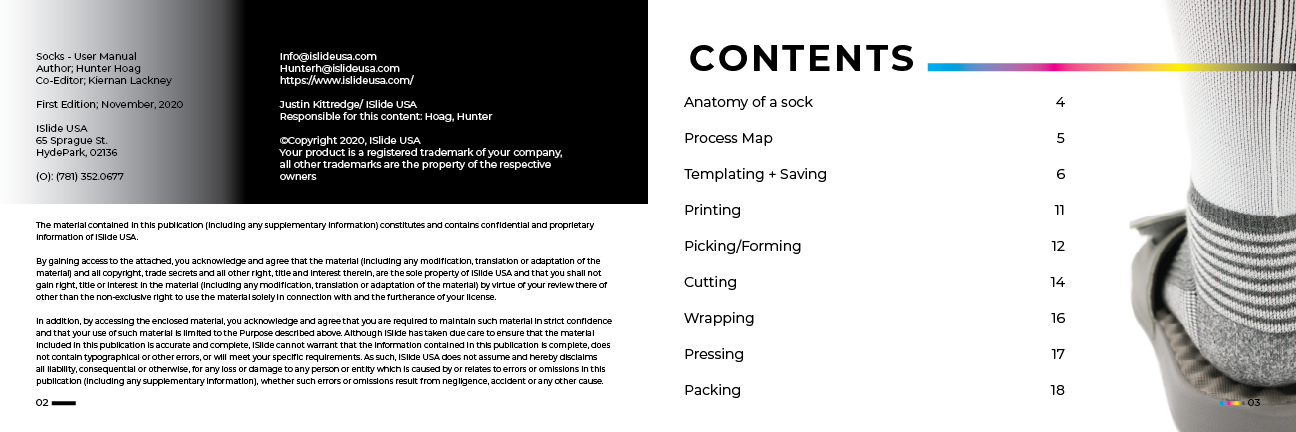

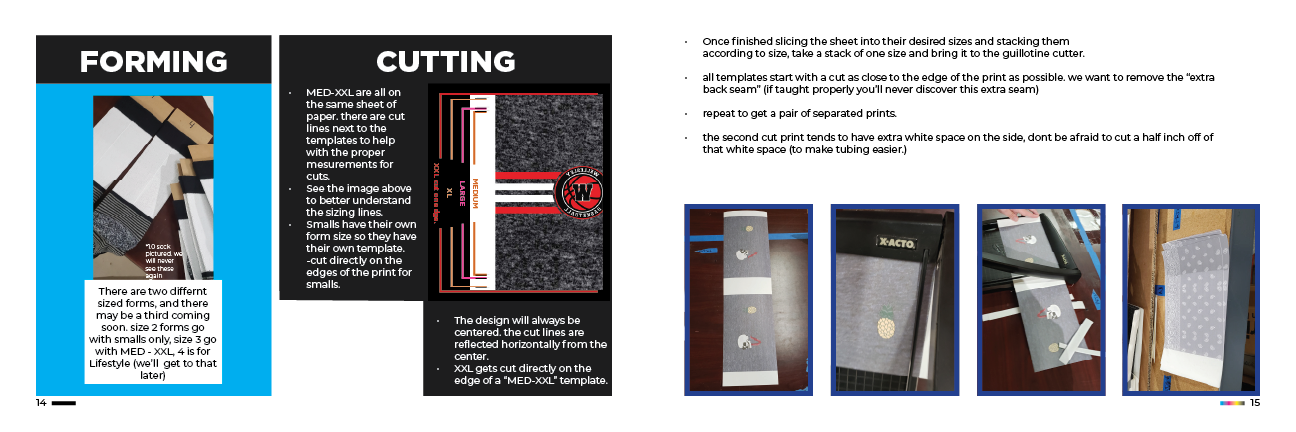

SOCKS

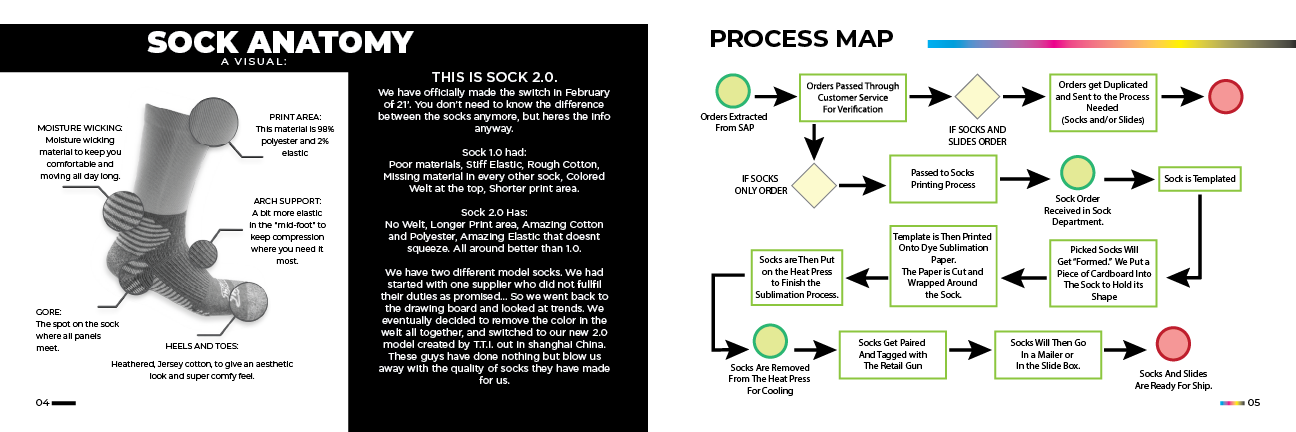

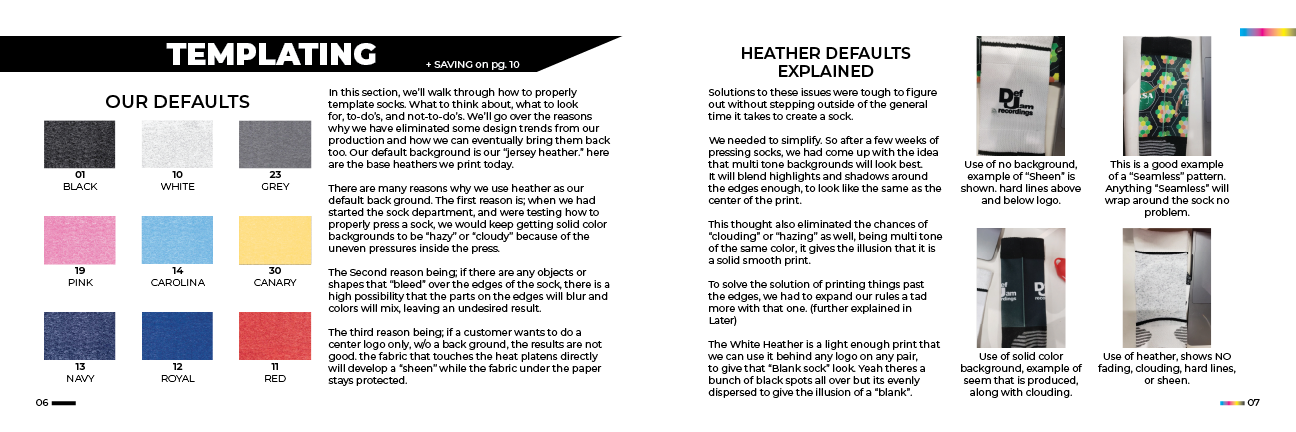

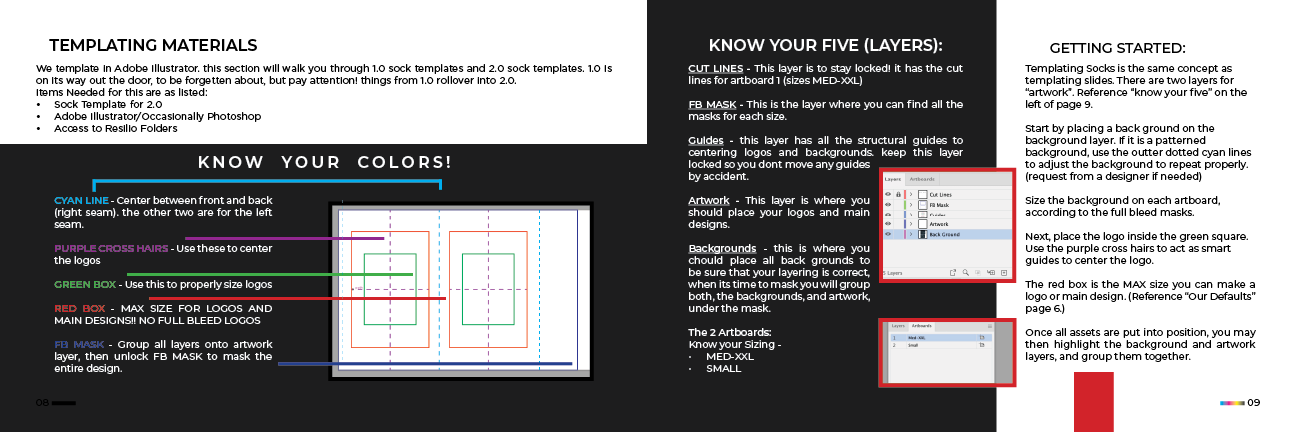

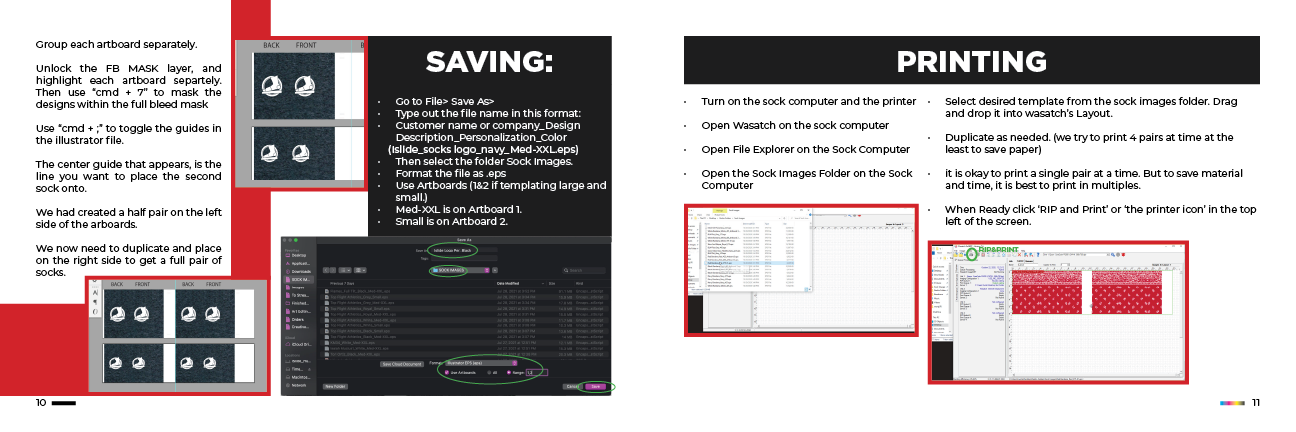

Socks production was a process of die sublimation and heat press. We printed directly onto a die sublimation paper to ensure customer designs were exactly what they asked for and they had full customization to create whatever they wanted. I Recorded and designed a "System Operating Procedure" to ensure easy onboarding for any new printer that joined the team.

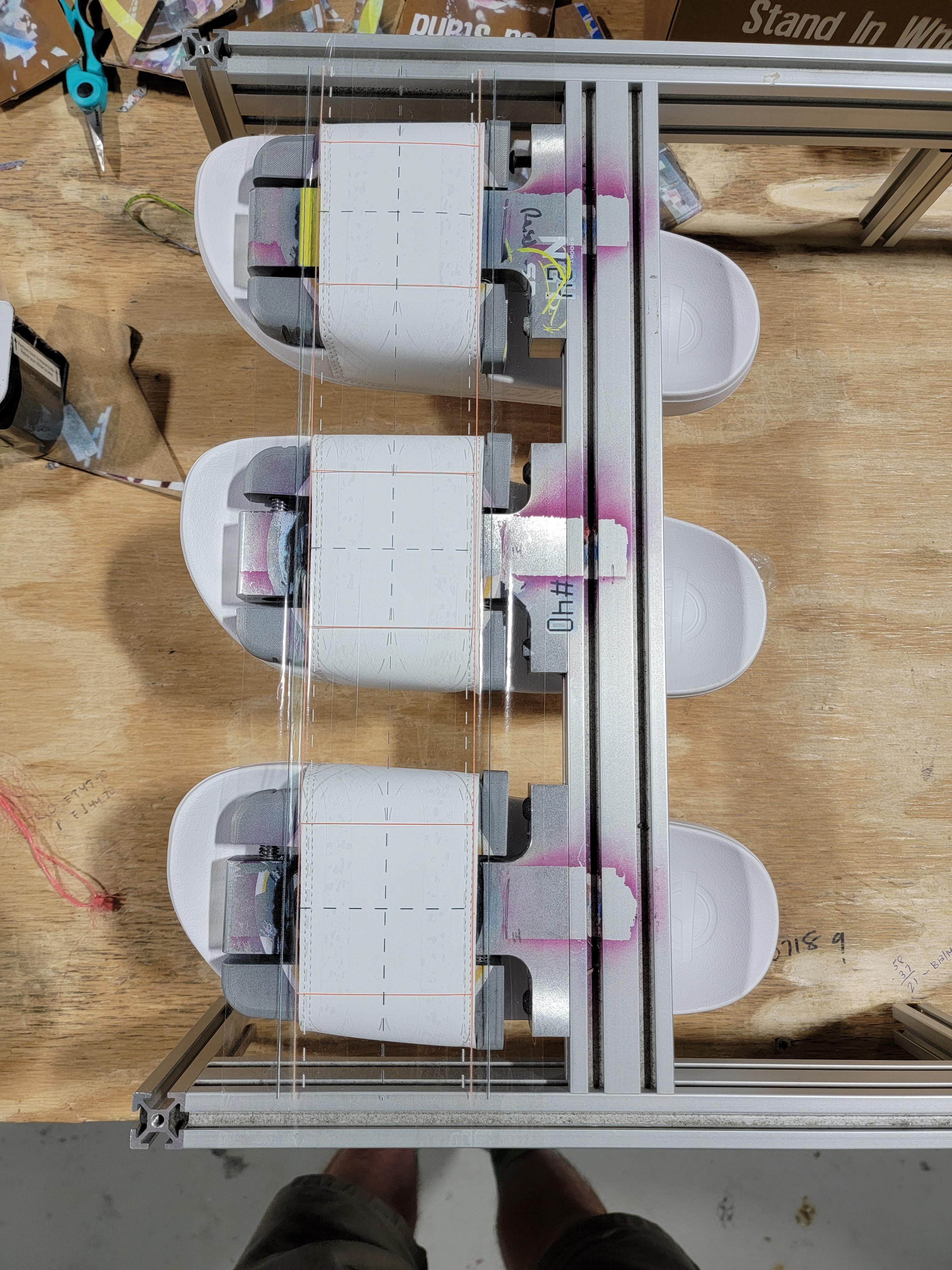

MOTTO - TEMPLATES

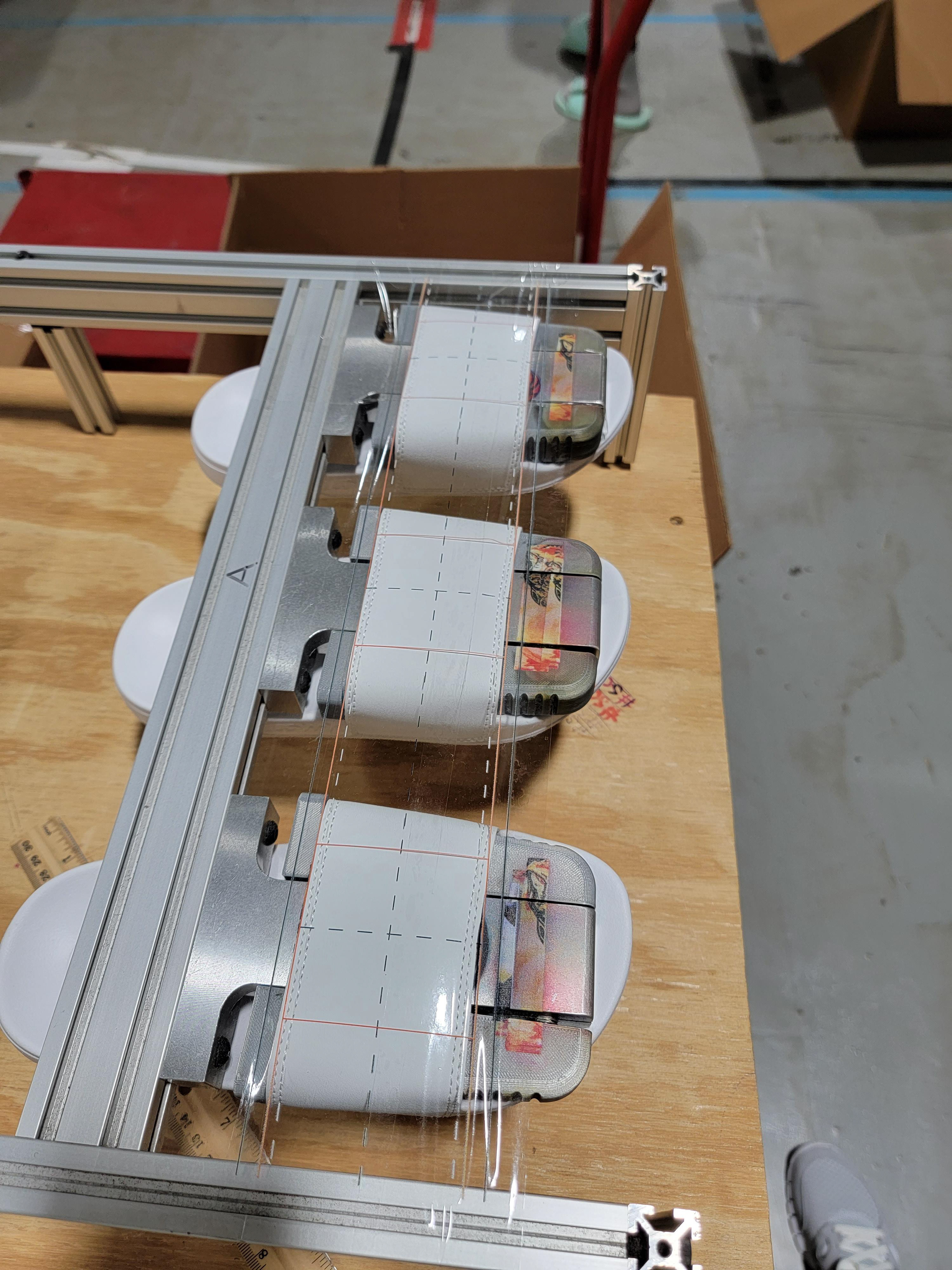

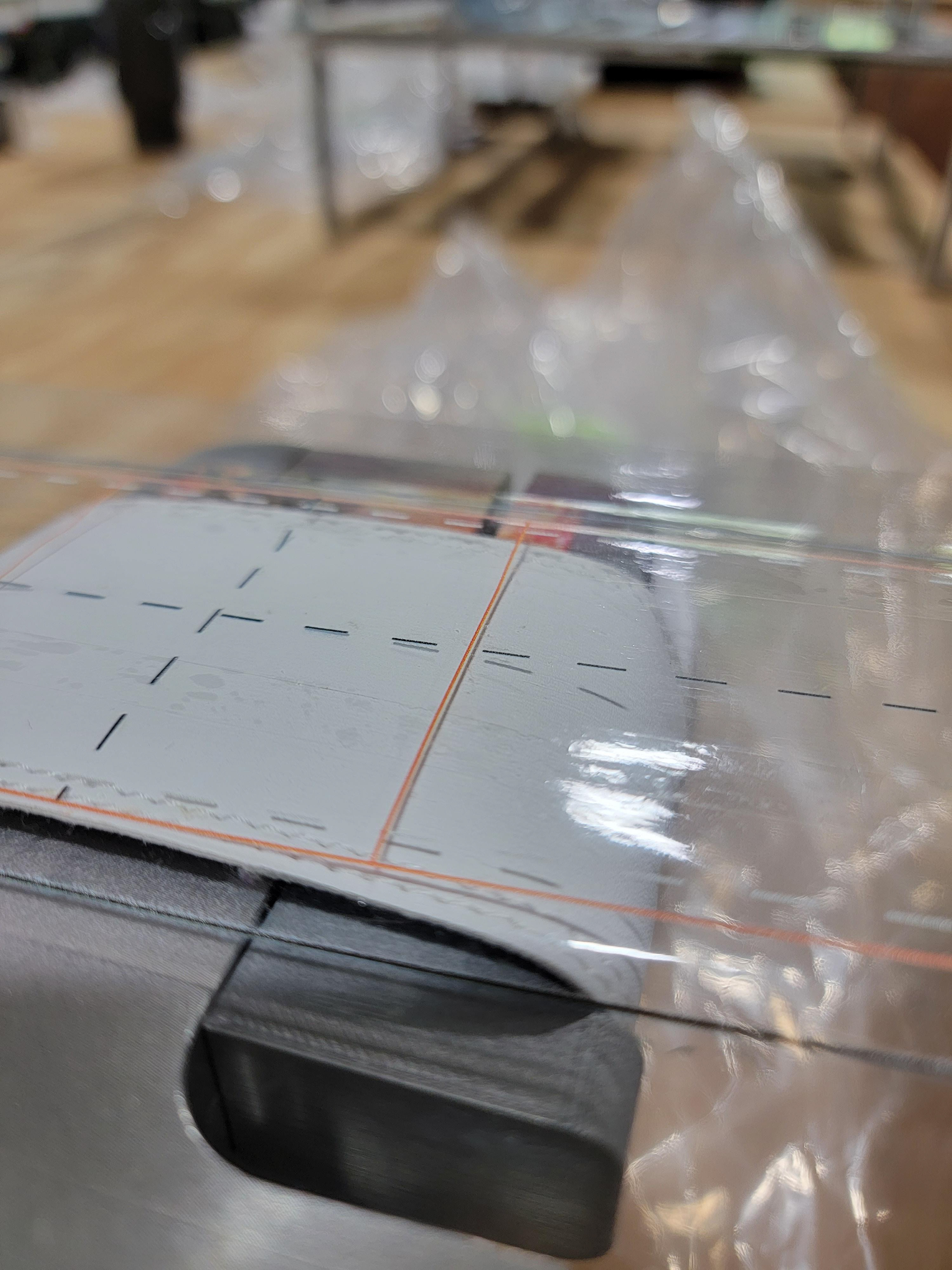

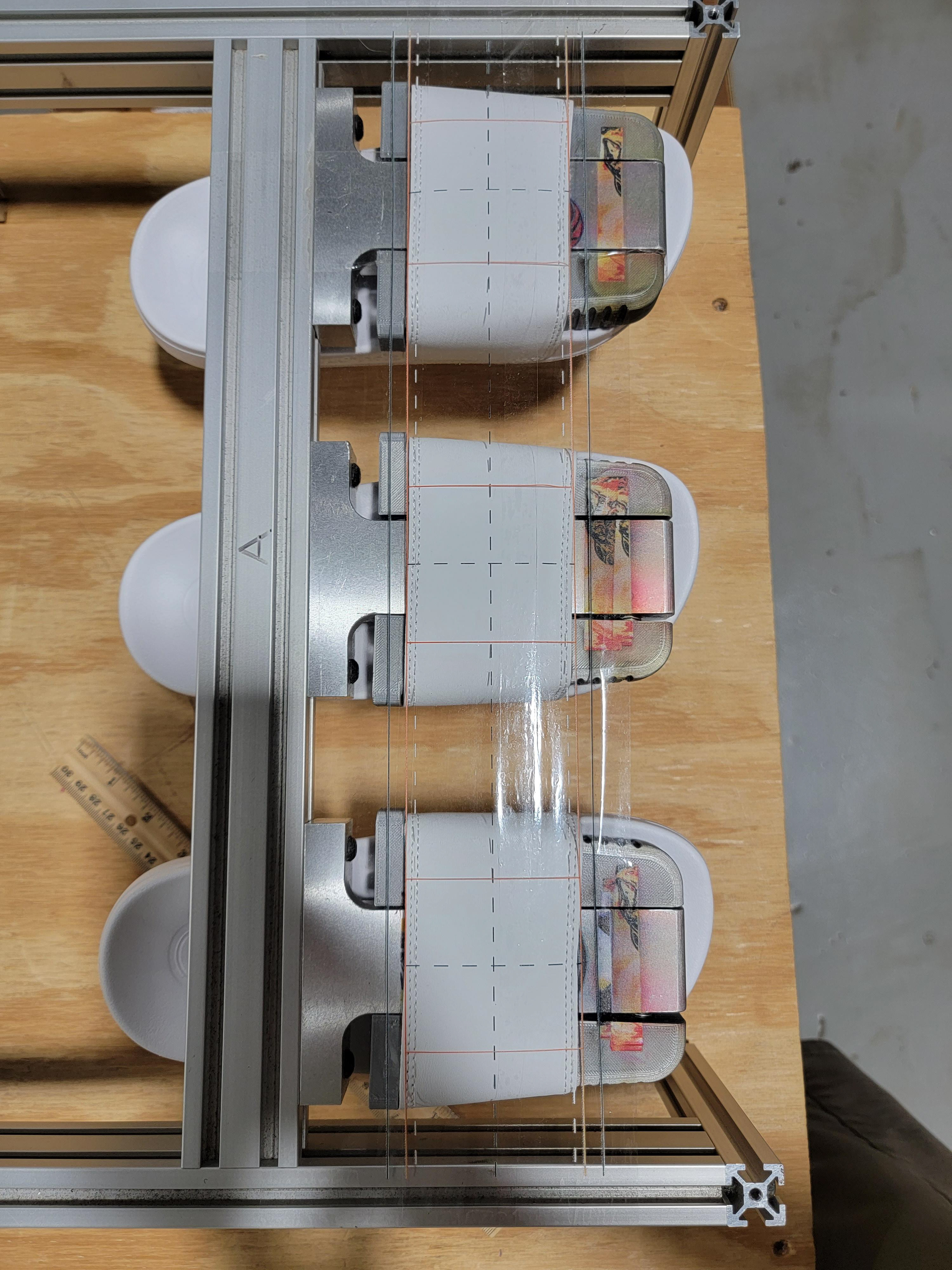

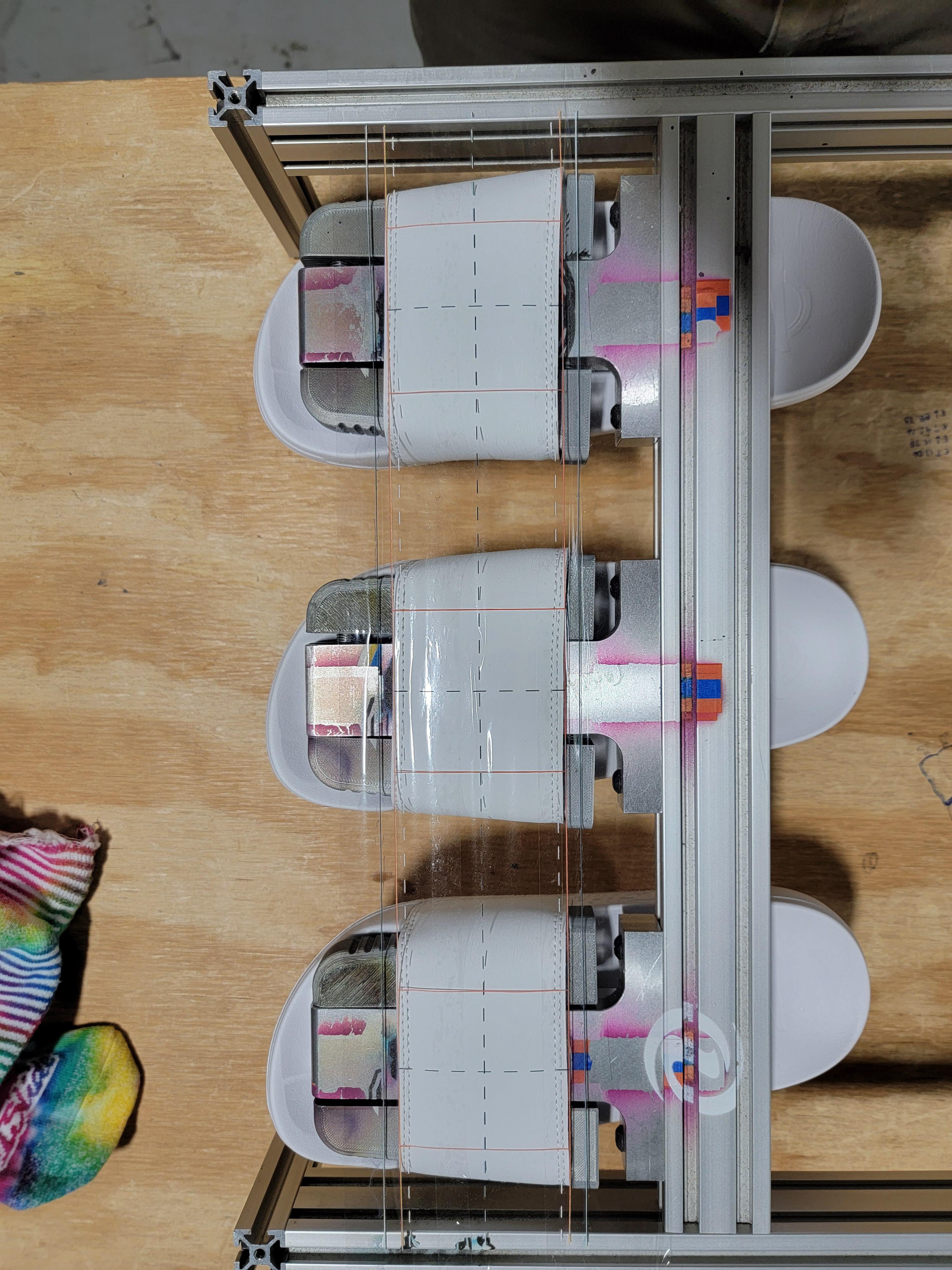

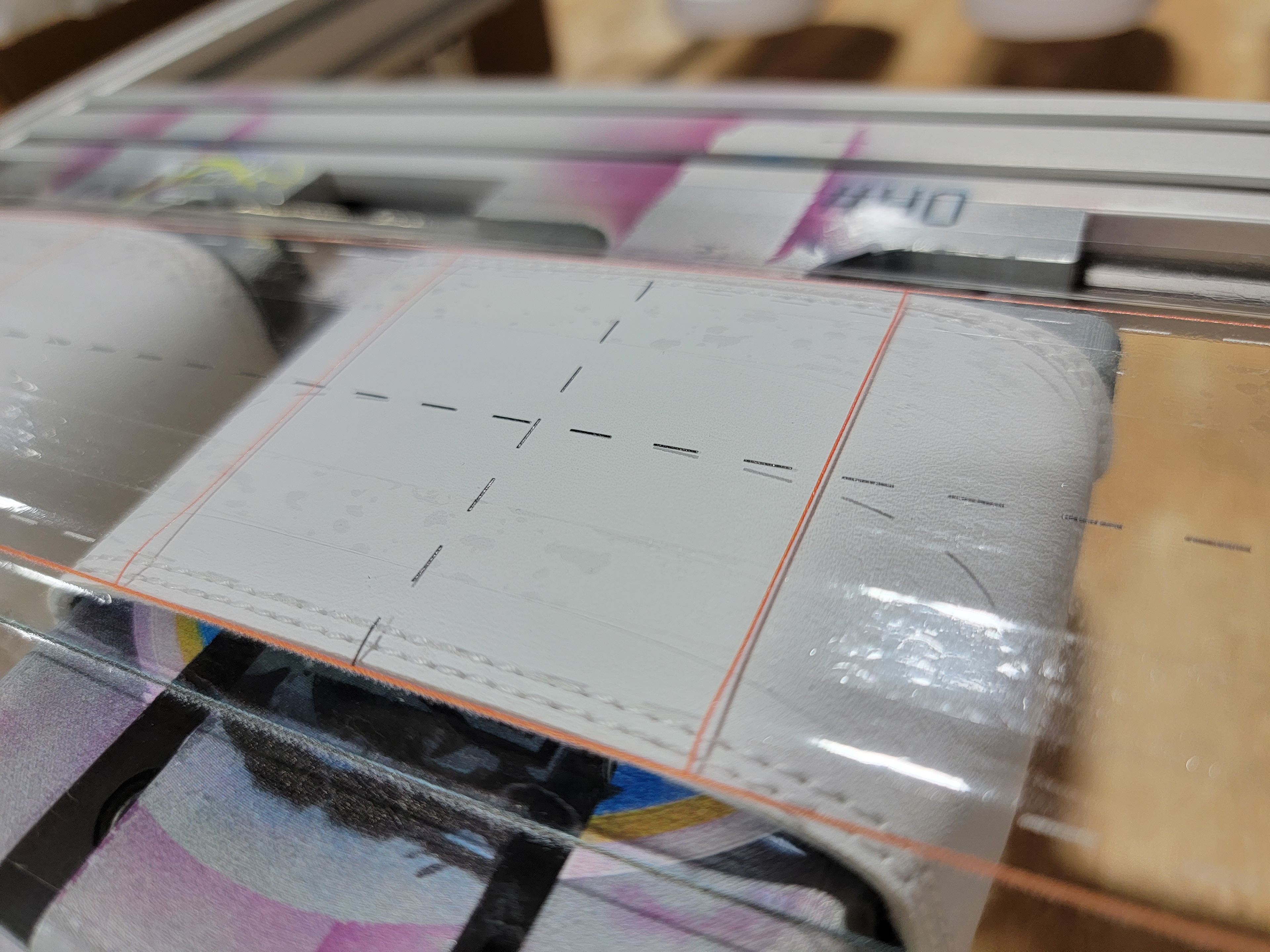

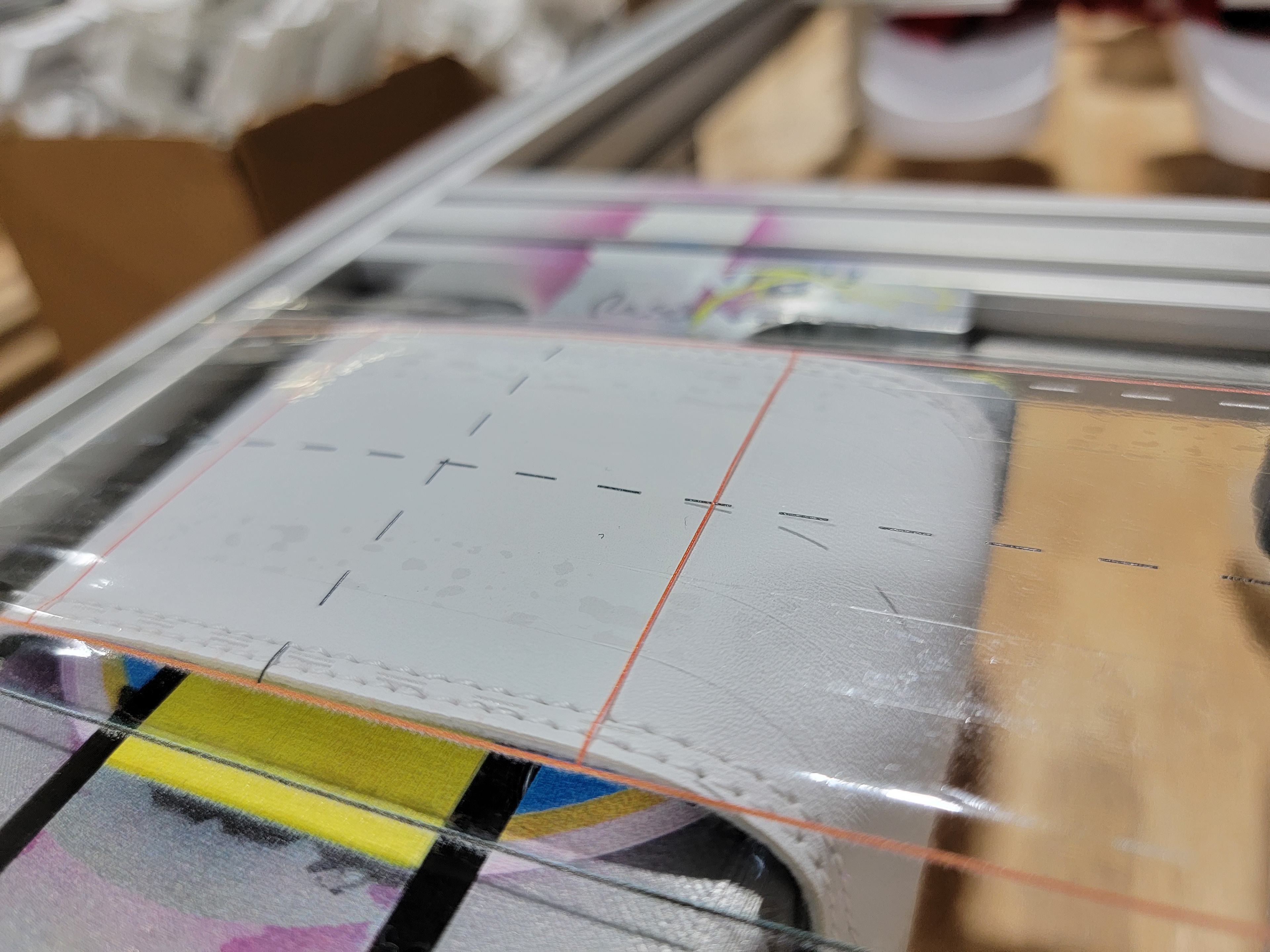

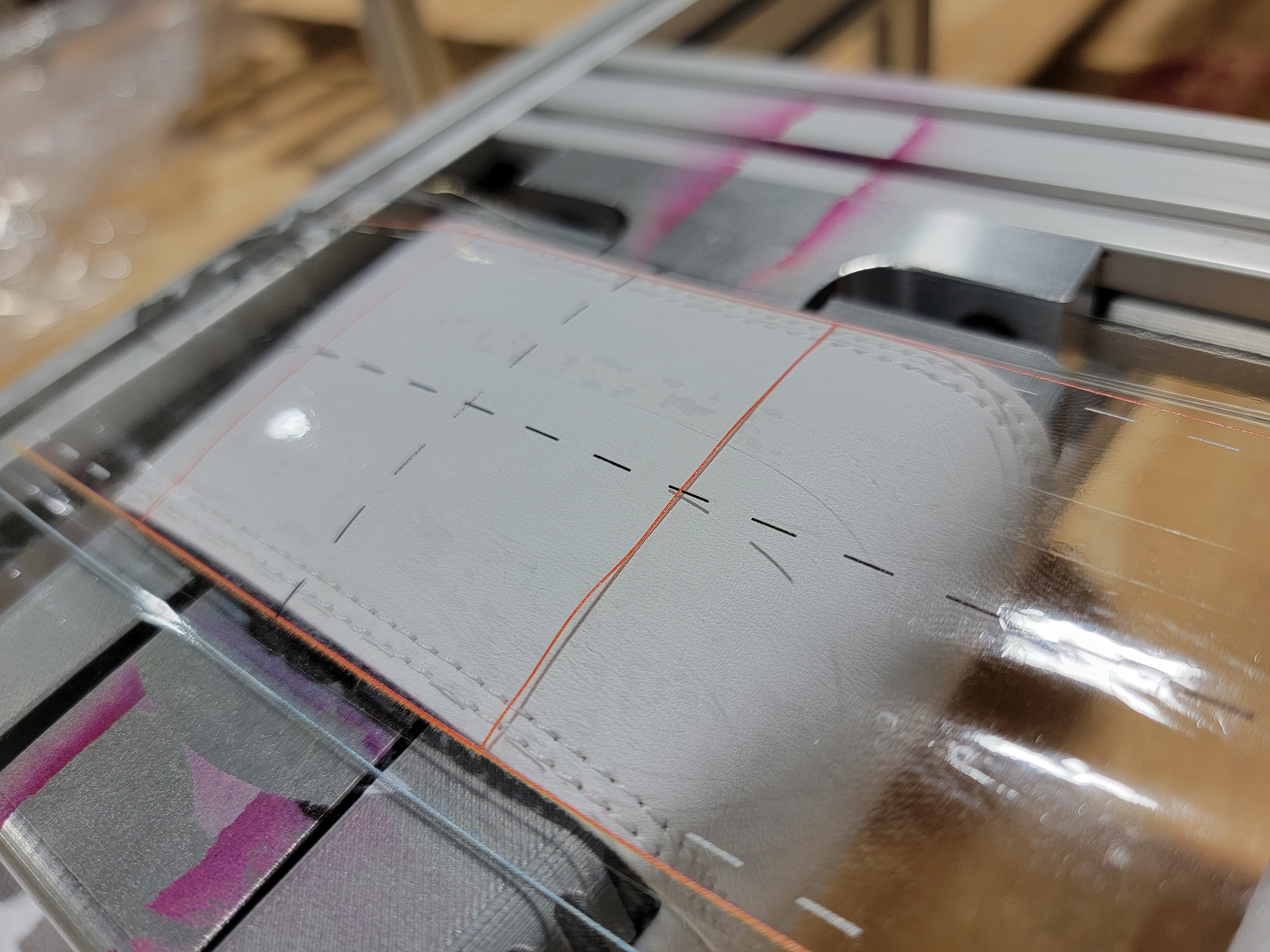

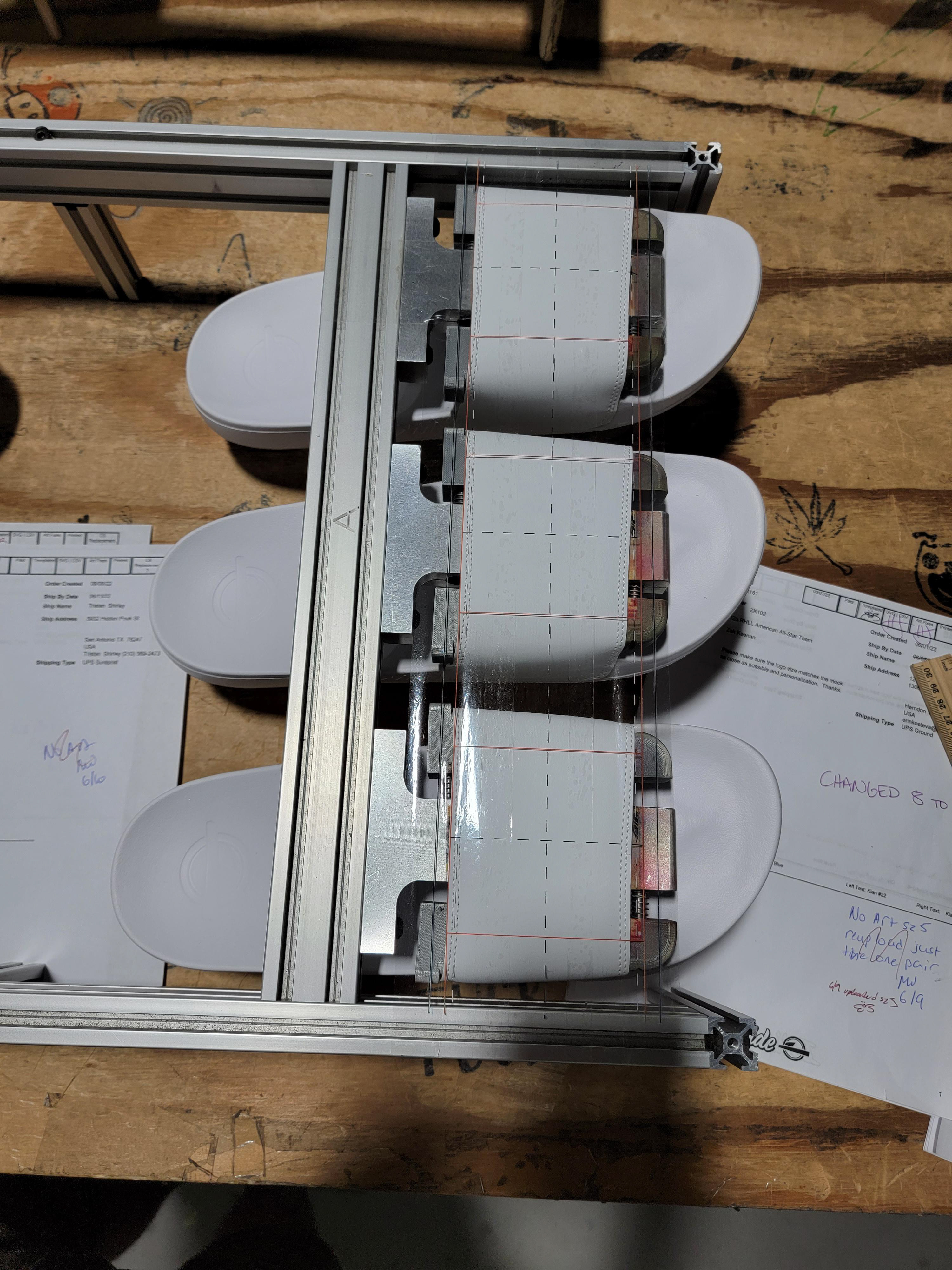

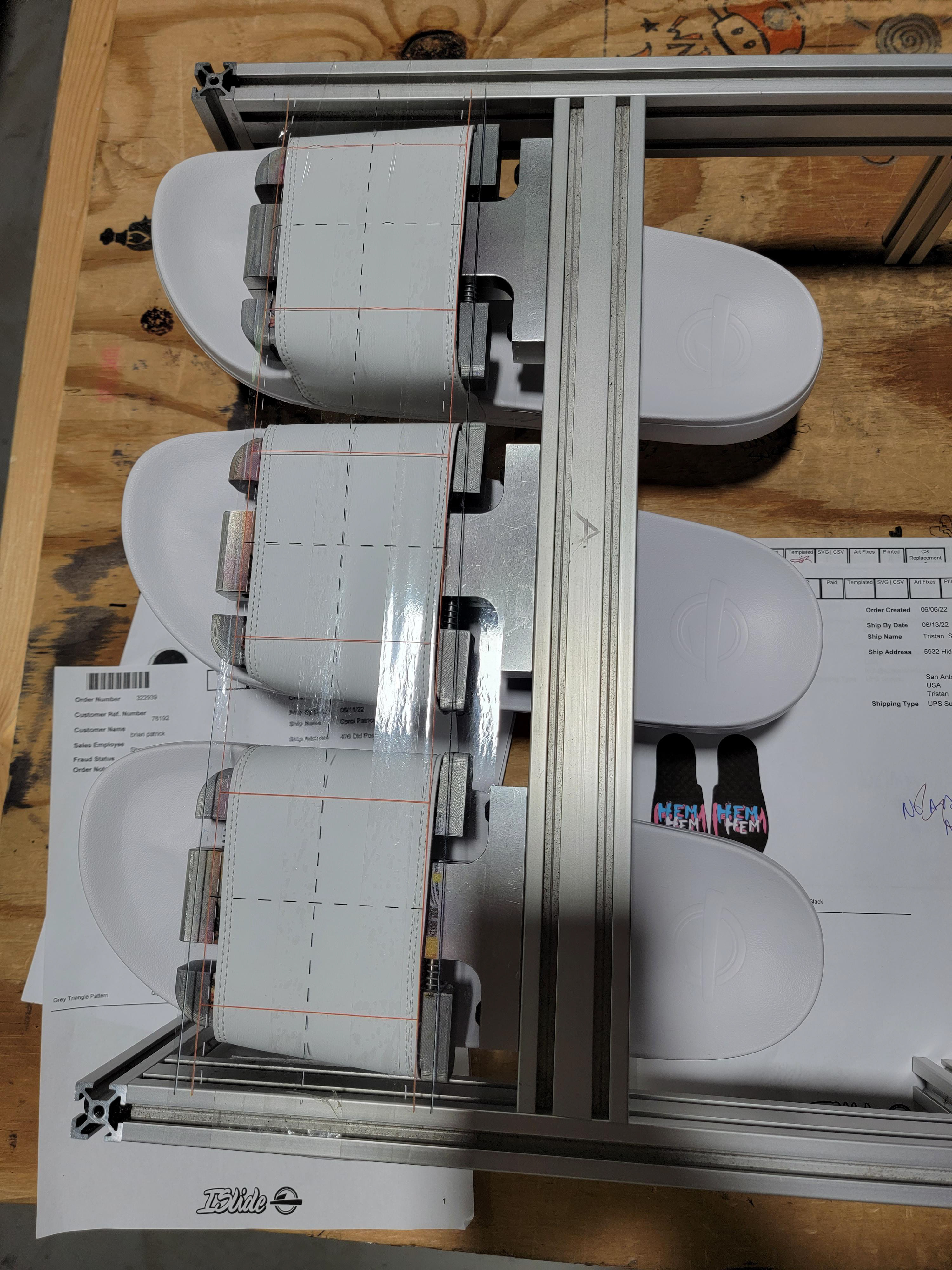

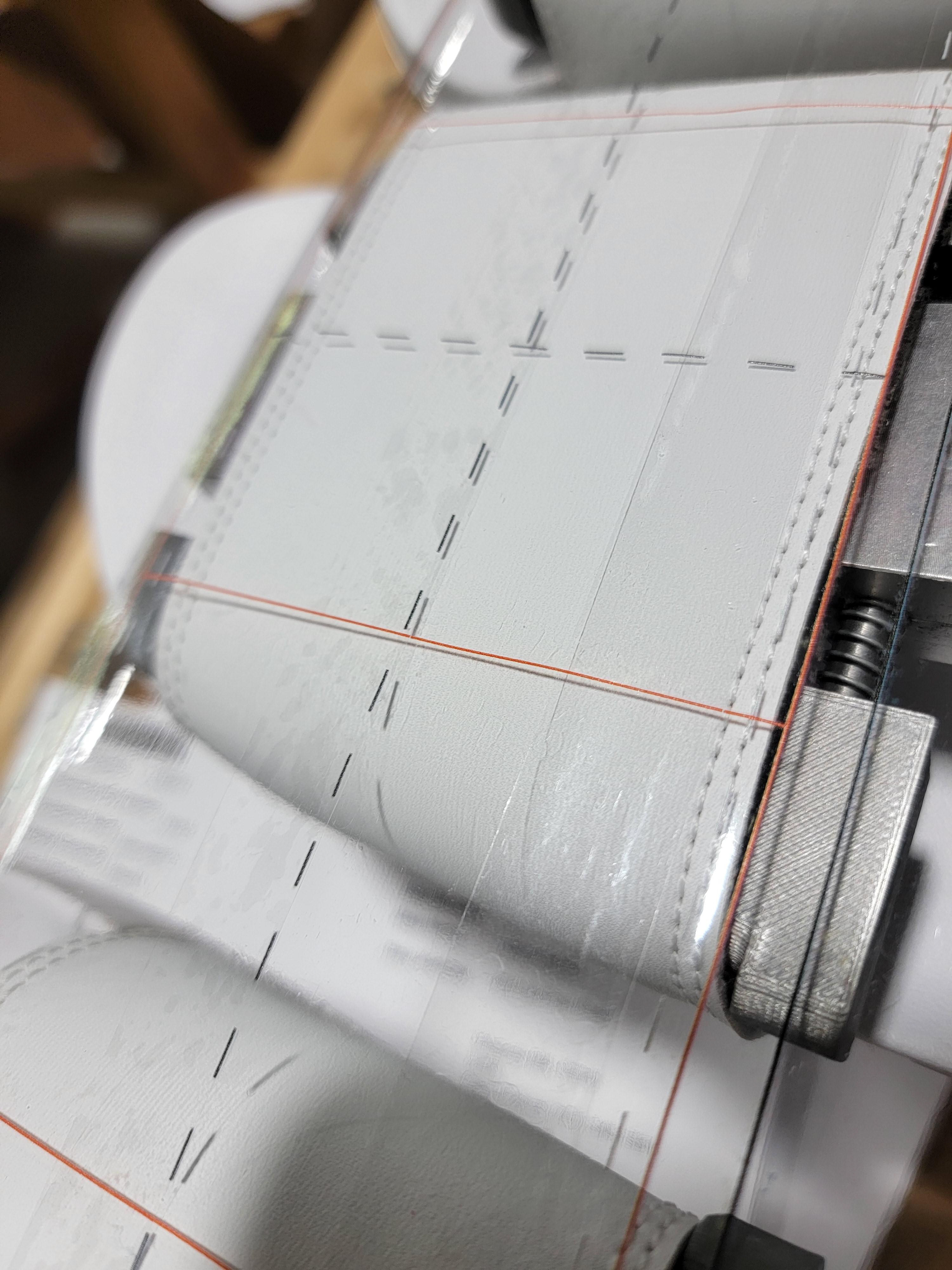

I assisted with the Jig, and completely re-templated the guides for the design team to guarantee accurate printing compared to our customizer. This ensured that sales reps were not overpromising by presenting a massive logo that we could not print. As a result, we reduced the loss of sales and the loss of product, caused by having to call customers back and admit that the print was not possible due to a mistake by our reps.

Check out the images below to see the testing. We needed logos to stretch as wide as possible without lifting from the strap. As shown in the images, we maintained a 6mm tolerance to achieve a clean design.