Socks and Slides are a very popular pairing for athletics and lounge wear. I had suggested to create a custom sock department as soon as I joined the team in 2019. We made it happen in 2020-2021. I was assigned to lead the project. Researching Production processes, Materials, Suppliers, and more. We settled on Dye Sublimation and Heat Press. It was the most versatile way we can customize socks, printing any design a customer threw at us. We could integrate this into our current design team and processes using illustrator and photoshop.

STATEMENT WAS AN IDEA

Print directly to a dye sublimation printer, printing 4 pairs of socks at once within 12 mins (one person). With two people on production we could produce 4 pairs within 6 minutes. Averaging 40 pairs of socks per hour. In an 8 hour day our best record was 1150 pairs with 4 people in the production line. We launched this product for a nationwide lacrosse tournament and created 7,200 pairs in 6 days.

This gallery below is Statement sock 1.0 as you can see we had a colored welt on top of the print area. this is the sock that was produced first. 100% created in the USA, Until...

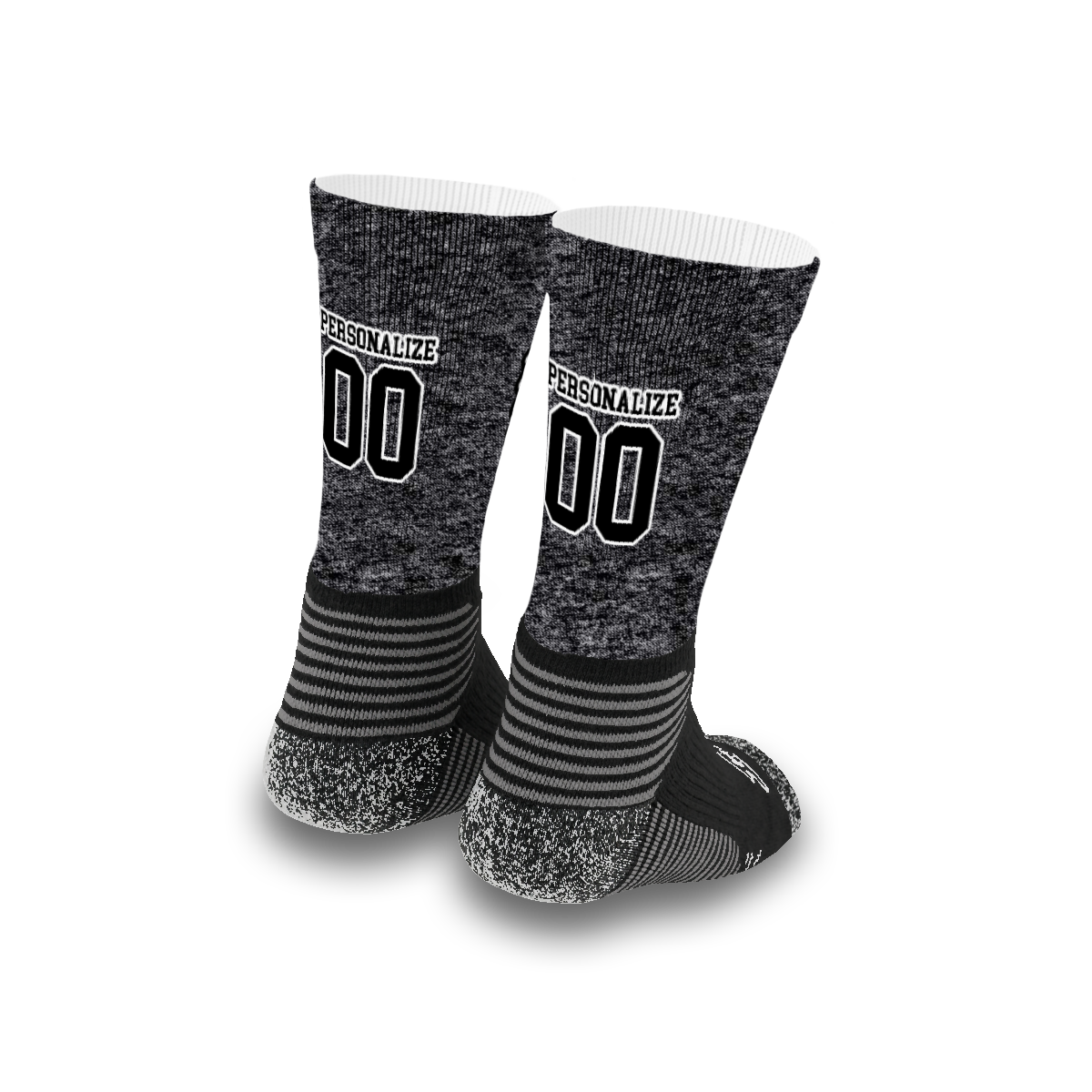

The print area was bland and looked bad post print with just a logo centered on them. I took the initiative to create perfectly colored textured backgrounds that matched the heal and toe of each color. "Heathered" is what we had called the texture. it was now our base design to place behind logos.

OUR CUSTOMERS DON'T KNOW WHAT THEY'RE LOOKING AT.

SOLVED. Before this was even an issue, I created mock ups for the front and the back, when the customers didn't understand our flat point of view. All mock ups use the same smart object so designers aren't jumping around from object to object and represents the real file accurately so customers know exactly how we're printing. all files (Flat, Front, And Back) will be saved at the same time and sent to the customer.

VIEW PACKAGING